PROCESS SAFETY

Roughly every year, since 2009, Citi Research releases a report ‘Safety Spotlight’ on injury and fatality data for Australia’s ASX100 companies, plus a few extra companies that are no longer in the top 100, but because Citi Research has data from their previous year’s reporting that they include them in the list of companies. Their most recent report was published in September 2016, but I thought it prudent to have a look at the insights from last year’s report as they relate to a webinar I recently hosted for the Australian Institute of Company Directors (AICD): The Board’s Role in Health & Safety Governance. In particular, the 2016 Citi Research Safety Spotlight: ASX100 Companies & More (the 2016 report) discusses whether investors should encourage a greater focus on the most critical safety risks (e.g. those risks from major hazards or process safety risks), rather than continued focus on aggregate injury data (e.g. personal injury data, represented in the form of lost time injuries (LTIs) and total recordable injuries (TRIs) in the 2016 report).

A specific focus in my AICD webinar was for the board to appreciate that monitoring personal injury data will not assist the board in preventing significant events as personal injury metrics are not good indicators of process safety, and a lack of understanding this has been implicated in major disasters (i.e. BP Macondo, Esso Longford). The 2016 report adds that where process safety / major hazard risks are potentially more material to a business, the board should have associated lead and lag indicators. I also highlighted in my webinar that regardless of a significant event, a focus on LTIs will not assist business leaders in getting a true picture of how well the business is doing at preventing injury and illness; this is discussed in the second post of this series.

This post is the 1st in a 3-part series that focuses on furthering the discussion between business leaders around:

- Developing lead and lag indicators that will assist the business in preventing and controlling the risk of a significant event, and be consistent with assessing the impact on health & safety when making changes to the business.

- Moving away from using LTI data as a measure of a business’ health and safety performance and introducing a new framework for standardising the reporting of injuries and illnesses that will assist the business in its pursuit to prevent harm.

- Improving the linkages between executive remuneration and the business’ health & safety performance.

BACKGROUND

The 2016 report covers 128 companies on the Australian Stock exchange as at June 2016 and includes injury rates as far back as FY05. Each year Citi Research provides additional research as an add-on to the report, and the 2016 report focussed on process safety and major hazard risk, the re-emergence of black lung disease in Australian coal, and FIFO mental health.

As of FY16, all but 11 of the 128 companies covered in the report are reporting on safety data in some form or another.

WHY BUSINESS LEADERS SHOULD READ THIS ARTICLE

This 2016 report can be used by business leaders to identify examples of better practice in health & safety performance reporting and to provide some informal benchmarking. However, one must be exercise due diligence when comparing performance data as there are no standardised set of metrics to easily and comprehensively compare businesses safety programs and performance. I will discuss this further in another post. Also note that I am not suggesting that the companies in the 2016 report, as a whole, are providing better practice reporting.

“The Safety Spotlight report is …compiled in response to continuing strong investor and company interest in their safety research and data”.

Citi Research

Furthermore, Citi Research adds that many of their investor clients, and perhaps even more so their corporate clients, use the report for benchmarking, refer to these reports in their own annual reports and advise Citi Research that the analysis is considered the ‘definitive’ dataset for Australia companies’ safety performance. As such, one may infer that if companies do not publicly report on workplace safety, it raises doubts about whether safety is being actively managed.

Finally, as a business leader, you should read this post if you think you need an introduction to process safety and/or would like to see what indicators ASX100 companies are reporting on in terms of process safety.

Process safety vs personal safety

I mentioned above that where process safety / major hazard risks are potentially more material to a business, the board should have associated lead and lag indicators, but let me start by giving an introduction to process safety, so that we are all on the same page …

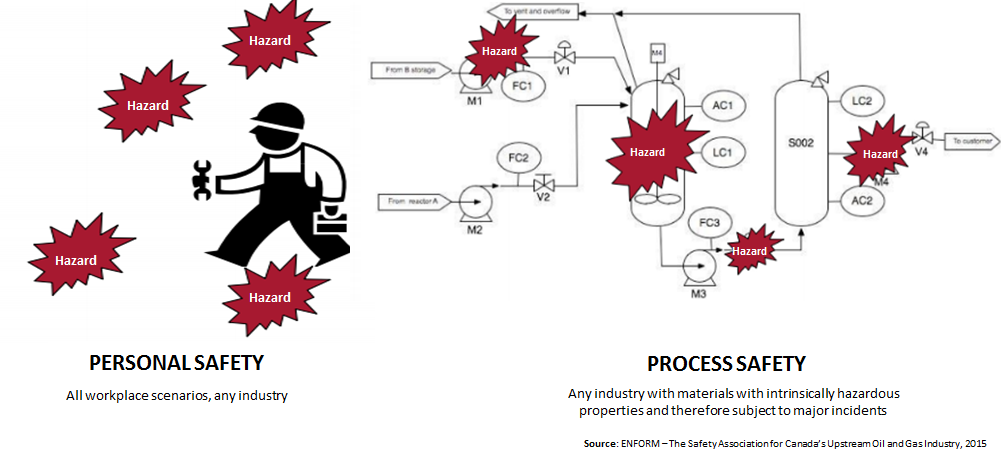

A process safety incident, is a single incident that can affect workers and the public (e.g. fire, explosion, release of toxins), where there is limited control by any given individual (e.g. controls are in place through a number of different methods or mediums), and can result in property damage.

The major hazard is normally considered to be the materials handled / processed in the facility and this applies to any facility that handles materials that are hazardous, either by virtue of their inherent properties or the conditions under which they are processed. This major hazard is controlled through a system of processes which include equipment and the individual as part of the system of work (e.g. resourcing needs to be sufficient, maintenance must be current).

So basically, process safety is a concept that deals with managing changes that will affect the safe process. Changes can be broadly grouped into: changes to people, equipment and technology.

Whereas personal safety, which most businesses are familiar with when thinking about preventing injury and illness, generally affects one individual, normally only the worker (e.g. slips, trips, falls, back injuries), and can be controlled by the individual (e.g. putting on their personal protective equipment, installing safety lines, following safe systems of work).

In short, as depicted below, if you think about hazards as those that can usually affect one individual, or a few (like falls from height, slip, trips), you are likely thinking about personal safety hazards; if you think about hazards in a process, particularly in process industries, then you are likely thinking about process safety.

Personal safety incidents have higher probability, but lower severity. Whereas, process safety incidents are less likely, but have much greater severity.

An absence of focussing on process safety data has been implicated in major disasters (i.e. BP Macondo, Esso Longford).

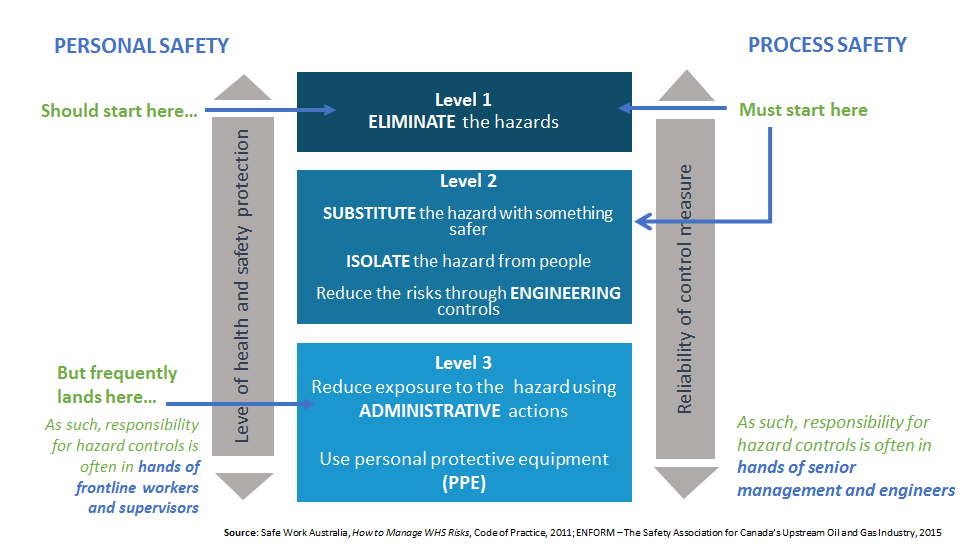

Senior leaders, in any business, across any industry, should consider whether the business has any major hazards that can cause a significant event (e.g. structural collapse, explosions, fires and toxic release) and develop lead and lag indicators to monitor how well the controls are implemented (lead) and effective (lag). The indicators for process safety cannot be the traditional personal injury metrics (e.g. LTI or TRI), this simply will not help the business manage the risk of a significant event.

A board with a mature safety culture will be able to comfortably talk to their major hazard risks and the processes in place to manage those risks.

They will also know the indicators they are monitoring that assist them in managing those risks. Additionally, the board will consider any impacts to the way health and safety is managed when they introduce change to the business.

In the 2016 report, 15 companies were investigated as to their approach to process safety / major hazard risk across inherent process safety industries including petroleum / energy, chemicals, utilities infrastructure and mining. Eleven of the 15 companies report on process safety / major hazard risk management, though comprehensiveness varied. The common process safety indicator, the unplanned release of hydrocarbon and dangerous occurrences, are lag indicators. The 2016 report suggests that more work needs to be done on identifying lead indicators, for example safety role competency, critical maintenance deferrals, deviations to safety critical elements, whether barriers fail on testing. Guidance on process safety management was recently published by several industry bodies, suggesting growing awareness of the risks, and acknowledged gaps in ‘know how’ for addressing the issue.

The last point I want to cover in this post is that that it’s important for business leaders to understand their role in process safety. For example, business leaders have more of a responsibility for controlling hazards in process safety, than front-line supervisors because process safety hazards need to be considered early in the process design and further up the hierarchy of control, which is where senior management, business leaders and engineers are more involved in decision making. In addition, business leaders need to actively discuss the health & safety implications from their corporate and strategic decision making, particularly where there will be change in the organisation. The Esso Longford tragedy was a particular example of where business leaders did not understand the impact to safety from their decisions regarding cost control and resource allocation (such as capital expenditure, equipment maintenance, training and human resourcing); as such, they had a significant impact on the events that occurred that day, even though they were far removed from the site at the time of the incident.

Thanks for reading!

Welcome!

I’m Samantha

I teach board members and executives how to lead with heart and put people first, by leading safe & healthy work. Stick around and I’ll share with you the skills, knowledge and mindset you need to know what to ask, and when to act and lead with confidence.

RESOURCES

YOU MAY ALSO LIKE…

FEATURED CONTENT

[text-blocks id=”4249″ plain=”1″]

Let us know what you have to say:

Want to join the discussion?Your email address will not be published.